Every day throughout the United States, trenches are dug to conduct waterproofing, build infrastructure, make repairs and work on utilities. Unfortunately, every day, workers enter these spaces without proper shoring. Regrettably, trenches fail, burying people under hundreds, if not thousands, of pounds of dirt.

A trench is a dynamic structure that has several different forces that act on it. Ultimately, the trench wants to collapse. The Occupational Safety and Health Administration (OSHA) requires with few exceptions that trenches that are deeper than 5 feet to be shored.

When rescue operations are required at a trench, it means that a dynamic event occurred. Crews must shore the trench for the safety of the patient and the rescuers. A general rule of thumb is rescuers shouldn’t operate in an unshored trench that’s deeper than their waist.

When was the last time that your organization assessed its shoring capabilities? Just as science is changing the way that departments fight fires, it also is changing the way that technical rescue operations are carried out, including the process of shoring a trench.

Shoring is much more than placing wood into a trench to hold back dirt. Shoring is an engineered system. Rescuers must understand the requirements of this system. There are strengths and limitations of the equipment, including lumber and fastening system, that’s utilized. The system must be installed properly to work within its engineering standards.

Know your limitations

You must assess your organization’s level of trench rescue training and capabilities. Operations-level personnel can shore straight trenches that are 8 feet deep. However, shoring of intersecting trenches and trenches that are deeper than 8 feet requires the expertise of technicians.

Although NFPA doesn’t define a maximum depth, OSHA requires trenches that are deeper than 20 feet to have a registered professional engineer calculate whether a shoring system can withstand the pressures of the trench.

A practice that’s employed by many teams is to train to a 16-foot depth, or two panels stacked. Just as an organization identifies its scope of care when it comes to emergency medical care, it must do the same for trench rescue.

Assess your equipment

Trench collapse shoring systems have two major components. The first of these is shoring panels.

Shoring panels commonly are 4 x 8-foot with a 2 x 10-inch strong back. Homemade panels must comprise two 0.75-inch plywood panels that are glued and screwed together as the minimum to meet the strength requirements for the process of shoring a trench.

Commercially manufactured panels consist of a 0.75-inch, 14-layer arctic white birch panel that’s specifically engineered for a trench. (These panels have a 2 x 10-inch strong back, too.) They are lighter than homemade panels.Crossmembers are the second major component of the shoring system. Crossmembers can be wood or commercially manufactured devices, aka struts.

Wooden crossmembers have limited strength. They commonly are calculated using Douglas fir. Teams that choose to utilize wood must understand the limits of wood.

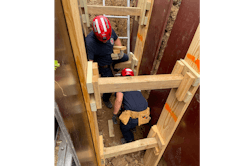

One of the largest disadvantages to wooden shores is that a rescuer must enter the trench to build the system. Remember, rescuers must remain on an exit ladder and build the initial system from top to bottom.

A strut costs more than a wooden crossmember. That said, it allows rescuers to lower and set shoring systems while these people remain outside of the trench. In these cases, the shores commonly are set middle to capture the panel; setting the bottom and top crossmember follows.

A good practice is to use a spool of paracord and lightweight carabiners to lower ropes to set the shores in place from outside of the trench. You should make enough ropes to leave them in place when the shore is set. This simple task can increase the efficiency of the operation.

It’s imperative that rescuers read and understand the user manual for struts, including operating pressures to set the shores, the method to lock the shore into place, installation limits and the storage method. Furthermore, rescuers must inspect and maintain the devices to ensure that there are no leaks.

Also, members must understand the yoke throw, how far that a strut can be deployed before it’s beyond its maximum, and the utilizations and limitations of extensions. Sometimes, just an extra inch or two is needed.

Exchanging bases can increase (by adding swivel bases) or decrease (by swapping out swivel bases for rigid bases) the overall length of a strut. In the former case, quickly adding two swivel bases can get you what you need.

During an equipment assessment, don’t forget the very basic equipment that a shoring team needs. This includes hammer, nails, saws and carpentry pouches.

Know your resources

In the absence of adequate trench-rescue resources within your organization or in the event that an incident is such that additional resources are required, you must identify where to turn for these—for instance, the municipal utility department, utility contractors and/or other fire departments.

When personnel who are from outside of the fire service are used, you must realize that trench rescue is much different than standard worker protection systems. Although personnel from outside of the fire service might have the necessary equipment, they likely won’t have training and experience in trench rescue.

Shoring operations

There are numerous ways to safely shore a trench in the event of a collapse. Each of these procedures involves varied considerations.

The force factors on shoring systems include fissures, or cracks, in the surface of the soil. These cracks indicate the extent to which the soil is moving and losing its cohesion.

Additional factors are loads on the surface because of spoil piles and equipment that are on the trench edge.

The most basic of shoring requires a top shore that’s within 2 feet of the lip of the trench, within 2 feet of the toe of the trench and no more than 4 feet in between (3 feet spacing when using wood).

A standard 4 x 8-foot panel requires at least two shoring members.Panels should be as vertical as possible. The creation of a V or inverted V with the panels can cause shoring members to pop out.

Shores should be level and square within the trench. The goal is to provide as much surface contact between the shoring crossmember and the strong back on the shoring panel as possible. This provides exponential dividends when it comes to the strength of the system and the safety of personnel who are in the trench.

When the entry team exposes more than 2 feet below a trench panel, additional shores must be put into place.

Waler systems are used to bridge support between several trench panels. Walers can eliminate one complete set of shores on a panel.

Walers commonly are used to bridge an opening in an intersecting trench or to create a larger work space around a patient. Although walers create more working space in the length of the trench, they restrict the working space in the width of the trench.

Traditionally, the fire service used 6 x 6-inch timbers to accomplish this feat. A renewed look at this practice has exposed its weakness. A 6 x 6-inch timber has very limited strength against the forces of a trench. Commercially manufactured waler systems can be three-and-a-half times stronger than the 6 x 6-inch timber yet substantially thinner. The utilization of commercially manufactured waler systems creates more working space for rescuers both in the length and the width of the trench.

Recently, laminated veneer lumber (LVL) has become an alternate to standard lumber when it comes to waler systems. A properly built LVL can be more than six times stronger than a 6 x 6-inch timber and 62 percent stronger than commercial waler systems.

Remembering your purpose

Your purpose on the incident is to rescue the patient. Patient care must be balanced into shoring and soil-removal operations.

The shoring team first must identify where the patient is or is believed to be and then set a three-panel set, when possible, to allow work for the entry team that’s extricating the patient and the patient care team. The patient can’t be safely extricated from the trench until you can see the arches of the feet.

Practice sets and repetitions in a concrete trench build confidence. That said, ultimately, a live trench is where skills are built. However, this is extremely high-risk training.

For many members, a trench collapse might be a once-in-a-career event. With multiple priorities on your plate, it’s easy to not prioritize practicing trench rescue. Nevertheless, the fact is that when the bell rings, you must have confidence in your skills, abilities and equipment.