Several weeks ago, I happened to be out at a fire department training center as the department trained with thermal imagers. The only training they planned to conduct was to get the flashover container hot and then go in and see what it looked like with their thermal imager. The thought was that full-scale, live-burn training was a waste of time when they could just fast-forward to "the worst imaginable scenario and see what the imager would do."

I asked them if this was something that they commonly ran into in the course of their firefighting, to which their response was, "We are an extremely aggressive department, so yeah, we see them all the time. Almost every fire, one of our crews is involved in a flashover!" Mistaking my hesitation as worry about damaging the imager, the firefighter leading the evaluation asked if I was scared. My answer was, "Yes, but not for the imager."

Flashover: A Threat To Firefighter Safety

You don't have to research very far to find information about firefighters who have lost their lives to a flashover. Plenty of information and training is readily available from multiple sources, but they all seem to come to one really simple conclusion: When a flashover occurs, you do not want to be there!

Being present at the moment of flashover is much akin to throwing yourself on the tracks in front of an oncoming train. Only bad things are going to happen. Your personal protective equipment (PPE) is going to provide only limited protection against this extreme event and the results can be devastating.

The International Society of Fire Service Instructors (ISFSI) produced a training program, "Flashover Recognition and Survival," in which it was demonstrated that an average firefighter, wearing full PPE and without a hoseline, can move at approximately 2½ feet per second. Given only two seconds to exit once a flashover occurs, simple math then establishes the "Point of No Return" as five feet from the entrance. Not very far, is it?

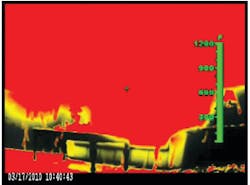

The reason is that flashover happens fast. The fire conditions progress rapidly from what was a hot fire to what becomes an inescapable fire. The images accompanying this column represent a six-second window of a fire conducted by Eastern Kentucky University last spring. We placed a thermal imager in the room and let it run as the room flashed over. You can see in Figure 1 that the fire is in its growth stage, but rapidly progresses through to a complete flashover in less than six seconds (red indicates temperatures in excess of 1,000 degrees Fahrenheit).

It should also be noted that flashover is a momentary phenomenon (see Figure 2). It is a small window of time marking the change from the growth stage to the free-burning stage. At any other point of the fire, the thermal imagery will look more like the image in Figure 3, which was taken just 39 seconds prior to Figures 1 and 2. The sudden release of BTUs and the disruption of the thermal layering that occurs at the moment of flashover is both sudden and dramatic and not the time to be looking at your thermal imager.

Flashover With A Thermal Imager

So how will a thermal imager help if you find yourself caught up in a flashover? Easy — it won't. If you find yourself inside an area at the time of flashover, the thermal imager can't do a thing for you. It's simply too late at that point. According to ISFSI, you have two seconds to react — five feet. If you spend even one second looking at your imager, you had better be closer than 30 inches from the door, since you consumed half of your escape time looking at the imager.

The problem here is two-fold. One is the mistaken belief by some firefighters that a flashover is an extremely common occurrence. The other involves claims that thermal imagers can generate an image during a flashover so that firefighters can find their way out. This then gives the firefighter the impression that being present during a flashover must be a common occurrence; otherwise no one would have developed a product with this scenario in mind. These are dangerous beliefs.

Pre-Flashover With A Thermal Imager

Pre-flashover is where your thermal imager can help and will pay for itself many times over. The fact remains that the only sure-fire way to guarantee that you survive a flashover is to not be there when it happens. You must recognize the signs of a pending flashover and then react to these signs so that you are safely out of harm's way (off the train tracks) when the flashover occurs (the train comes through).

Your thermal imager cannot predict a flashover. It will not tell you or alert you that a flashover is pending; however, it can give you a visual indication of warning signs you would otherwise not see. Without a thermal imager, thick smoke acts as an effective visual barrier to what is going on at the ceiling. Convective velocity, thermal layering and even rollovers are often hidden inside the smoke and are difficult or impossible to detect. The thermal imager has no problem visualizing these events. With the thermal imager, you can often get a good read as to how rapidly the fire gases are moving across the ceiling (indicating they have someplace to go rather than being confined to the room you are in).

Thermal layering is also very often visible to the thermal imager, if not directly (visualization of the fire gases themselves), then indirectly (by looking at vertical wall surfaces for indications of temperature differences). When either of these two things change, convective velocity slows or thermal layers descend, it can serve as early indicators of potential flashover conditions.

You can use your thermal imager to scan a room prior to entry. Look for signs of excessive heat buildup, particularly near the ceiling, or indication of high heat closer to the floor where you may not otherwise expect it. If your imager is equipped with high-heat colorization, you should make sure you are familiar with the corresponding temperatures associated with your particular color system. Use your thermal imager to locate potential vertical or horizontal vent points in case you need them and always use your thermal imager to know where the secondary means of egress are located.

Again, all of these tactics are directed at recognition and avoidance. This is where the thermal imager is effective. You must get out of the way if you have no other means of control (ventilation, hose stream, etc). If you wait until the flashover is taking place, it is too late for the imager, or anything else for that matter, to be of much help.

A Word of Caution

There is one other cautionary note that I want to convey clearly. The temperature-sensing function of your thermal imager is not a reliable indicator of flashover or pre-flashover conditions. (For a more detailed explanation of the capabilities and limitations of temperatures sensing, please see "The Truth Behind Temperature Sensing — Part 1 and Part 2" in the April and May 2009 issues of Firehouse® Magazine.) Although much has been written about what temperature range(s) commonly exist during a flashover, do not be tempted to rely on the temperature measurement function of your thermal imager to determine safe or not safe. Even though the imager is equipped with a three- or four-digit number that tells you the temperature, these devices simply are not reliable enough to bet your personal safety on. This is true for all manufacturers of thermal imagers. No one imager's ability here is any better or worse than any other.

The first concern is that the temperature-sensing capability of your imager cannot accurately detect the temperatures of gases, which is where the greatest threat usually lies in the growth stage of a fire. Thermal imagers are designed to detect surfaces, but not gases. The second concern is that, as temperatures rise, the imager's temperature-sensing margin of error grows correspondingly. A 10% margin of error in ambient temperatures only indicates a seven-degree accuracy question; however, at high temperatures, many thermal imagers will increase to a 20% or higher margin of error, which can represent a 200 degree or greater measurement error at 1,000 degree temperatures in controlled conditions.

Conclusions

Obviously, a lot of attention is being paid to flashover training and understanding throughout the fire service and for good reason: 2010 was one of the lowest years for firefighter line-of-duty deaths that we have seen in some time, at 87; however, by calling a training "flashover training," we may be inadvertently giving the impression that flashover is a routine event rather than a culmination of successive, prior events that can lead to a potentially catastrophic outcome for the firefighter. It is these pre-flashover events that you must train for. In the same way that you size-up a building prior to entry, you must constantly size-up the interior conditions and be observant of change, because avoidance is the only sure-fire pathway to survival.

"Know your enemy and know yourself and you can fight a hundred battles without disaster."—Sun Tzu

BRAD HARVEY is the Thermal Imaging Product Manager at Bullard. He is a veteran of public safety as a firefighter, police officer and paramedic and is certified through the Law Enforcement Thermographers' Association (LETA) as a thermal imaging instructor. Harvey has worked as a high-angle rescue instructor and is a certified rescue technician and fire instructor. If you have questions about thermal imaging, you may e-mail him at [email protected].

About the Author

Brad Harvey

BRAD HARVEY is the Thermal Imaging Product Manager at Bullard. He is a veteran of public safety as a firefighter, police officer and paramedic and is certified through the Law Enforcement Thermographers’ Association (LETA) as a thermal imaging instructor. Harvey has worked as a high-angle rescue instructor and is a certified rescue technician and fire instructor. If you have questions about thermal imaging, you may e-mail him at [email protected].