Behold the beam, an amazing structural element that bends when loaded — but one that must not bend too much. A fallen tree spanning the banks of a river was perhaps the first beam used by primitive man for a specific purpose: to see what's on the other side. That fallen tree was an accidental beam.

Part 2

Beam Configurations

Let's consider the six basic beam configurations that you are likely to encounter during pre-incident planning:

- Simple

- Restrained

- Continuous

- Cantilever

- Overhang

- Suspended

1. Simple beam — As mentioned previously, a simple beam is a single-span beam supported — but not restrained — at each end. Because its ends are not restrained, the entire length of the beam can deflect when loaded. Due to compression and tension within the beam, the material at each beam end is free to rotate. The beam shown in Figure 1 and Figure 2 in part one of this article (July 2010) is a single-span, simply supported beam.

When heated, an unrestrained steel beam is free to elongate, elongation generates lateral thrust. Axial column/beam assemblies are not designed to resist thrust. In this context, think of thrust as a lateral outward push.

2. Restrained beam — At first glance, a restrained beam looks like a single-span simple beam. However, because each end is rigidly fixed (Photo 1), it cannot move; clockwise rotation is restrained. A restrained beam is also referred to as a fixed-end beam.

Like the column described previously, should a 40-foot unprotected steel girder be heated to 1,000 degrees Fahrenheit, the girder will want to elongate about four-inches. If the girder is rigidly restrained, it will not be able to elongate. The restrained steel girder will release the elongation energy by twisting (torsion). Girders support other beams (purlins and/or joists). These beams often support the floor above or the roof. As the girder twists, these beams are compromised; loads are transferred, axial becomes eccentric and factors of safety disappear. Heat-induced structural shifts can produce seismic-like results.

3. Continuous beam — A single-span beam extending over three or more supports is a continuous beam (Photo 2). Because the single-span beam continues over the middle support, multiple-curvature is generated. There is simple beam sag between the supports and an upward curve reaction as the beam passes over the middle support.

This becomes strategically significant should a continuous beam become a simple beam during a fire or because a forklift accidentally backs into and buckles a column. This can happen if a middle support fails. If the middle support is a 40-foot unprotected steel column that heats to 1,000°F, the column will want to elongate four inches. (Imagine the amount of energy required to stretch a 40-foot steel column by four inches.) If compressive loading prevents the column from elongating, it will release that energy by buckling (deflecting). When a column deflects (bends), it is no longer a column; it has become a vertical beam. Beams bend, columns don't bend.

With the loss of the center column, the continuous beam has just become a simple beam. This means that the load carried by the center column has been transferred to the end supports. This load redistribution arrives at the end supports as a dynamic impact. Can the columns or bearing walls support the extra load? You do not want to own this situation if you are the incident commander.

4. Cantilever beam — A cantilever beam is also a single-span beam, but only one end is supported. To maintain equilibrium, the end support must be rigid enough to resist rotation (similar to a lever). The supported end is "restrained," which means it cannot move (thrust) or rotate (lever) when the cantilever is loaded.

Try this: Stand up and extend one arm perpendicular to your body. One end of your arm is supported by your shoulder assembly and the opposite end is unsupported. You have just created an anatomic cantilever. In a cantilever, the top portion of the beam lengthens; thus, the stress is tension; the bottom portion of the beam shortens, thus the stress is compression.

Think of cantilever beam action as that of a first-class lever (like a pry bar) with one fixed end.

As with all structural systems, the connection is the weak link. True single-span cantilever beams are rare in building construction.

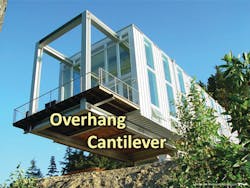

5. Overhang beam — Overhang beam reaction produces both simple and a cantilever beam action (or continuous and cantilever beam action). Between supports you've got simple beam behavior (or continuous). Instead of terminating at the supports, the beam extends over and beyond the supports — overhangs — thus becoming a cantilever. As the beam extends beyond the support, simple beam deflection is reversed and cantilever beam action is generated. A good example of an overhang beam is a diving board (photo 4).

When loaded, a single-span simple beam and a single-span cantilever beam deflect into a single curvature shape between their supports. The simple beam curve exhibits sag between the supports (the smile shape); the cantilever beam sags at the unsupported end. An overhang beam has at least two curvatures. (If there is overhang beyond both supports, there will be a cantilever on both ends.) The first is the simple-beam sag between the supports; the second is the cantilever sag at the unsupported end.

Overhang cantilevers (Photo 5) are much more common in building construction than true single-span, single-connection cantilevers. A "double-overhang" beam is simply a beam with overhangs at both ends, such as a classroom tabletop that extends at both ends beyond the legs. (If the tabletop terminates at the legs, it is a simple beam.)

6. Suspended beam — At first glance, a suspended beam looks like a cantilever: a single-span with one end supported and restrained. The key difference is at the unsupported end. Rather than hang free like a cantilever, it is supported by a member in tension. This member is often a hot-rolled steel rod or a cold-drawn steel cable.

Suspension systems are the reverse of the traditional structural hierarchy that includes beams, columns, and bearing walls. The traditional structural hierarchy sends load sideways and down. A suspension system thumbs its nose at gravity by sending the load upward. However, as the saying goes, what goes up must come down. Recall that all dead load and live load must eventually arrive at the earth as compression. At some point, the suspended load going upward must turn sideways (usually at a girder or purlin) and be sent down through a compressive member (column or bearing wall).

Do not confuse a suspended beam with the so-called suspended span. A suspended span is a variant of a cantilever bridge. With this bridge system, simple cantilever spans are formed by two cantilever arms extending from opposite sides of the span to be crossed, such as a river. Because the cantilever arms do not meet in the center, they support a mid-span truss section that is "suspended" by a connection at each end of the cantilever arms; thus, the middle span completes the main span. In this case, the tension travels sideways to the cantilever arms. (Note that the combination of anchor arm and cantilever arm exhibits characteristics similar to the overhang discussed previously.)

There are two important strategic considerations for structural suspension systems: their dependence on tension and their lack of mass. Size, rigidity and mass are required to support a given load in compression. The same load supported entirely in tension can be transferred through a component that is slender, flexible and comprised of much less mass (material). Less mass means less resistance to heat — not just fire, but heat.

Pure compression structural components send their load downward and pure tension components send their load upward (to other components that eventually send the load sideways and down). Up is also where the heat from a fire goes. Tensile structural components are the only structural systems that send load up before sending the load down to the earth.

Within the hierarchy of a building, unprotected steel exposed to high heat is not a winning combination. Hot-rolled steel rods and reinforcing bars (rebar) retain much of their strength until heated to about 800°F; cold-drawn steel cables (and pre-stressing strands) begin to lose strength at around 500°F.

There can also be structural cables on the exterior of a building. Photo 6 and Photo 7 show a dormitory building (now demolished) at Central Washington University in Ellensburg, WA. Note the unprotected steel cables running up the face of the building. Much like a suspension bridge transfers the bridge deck load to the towers, these cables transfer the live and dead floor loads to towers on the roof. Each floor is suspended by cables that stretch in front of the windows and behind the wall panels between windows.

To Be Continued

In the first two parts of this article, we discussed basic beam behavior and six basic beam configurations. Next time, we will "behold" (and discuss) the 12 beam types:

- Sawn wood

- Laminated-strand lumber (LSL)

- Parallel-strand lumber (PSL)

- Laminated-veneer lumber (LVL)

- Glue laminated lumber (Glulam)

- I-joist

- Built-up

- Flitch

- Box

- Wide-flange

- Lite-steel (LSB)

- Pre-stressed, pre-cast concrete

MARK EMERY, EFO, is a shift battalion chief with the Woodinville, WA, Fire & Life Safety District. He is a graduate of the National Fire Academy's Executive Fire Officer program and an NFA instructor specialist. Emery received a bachelor of arts degree from California State University at Long Beach and is a partner with Fire Command Seattle LLC in King County, WA. He is in no way affiliated with or an advocate for the truss manufacturing or building construction industries. He may be contacted at [email protected] or access his website www.competentcommand.com. Part 1 was published in the July 2010 issue.