Cordless Reciprocating Saws - Part 3

Understand Reciprocating Saw Bi-Metal Blade Design and Function.

Subject: Cordless Reciprocationg Saws, Part 3

Topic: Selection and Use of Bi-Metal Blades for Reciprocating Saws at Vehicle Rescue Incidents

Objective: Understand Reciprocating Saw Bi-Metal Blade Design and Function

Task: Select the correct bi-metal blade for rescue use and demonstrate proper use of the blade in a reciprocating saw.

The fire service is becoming increasing familiar with the operating capabilities of reciprocating saws. They are being used in unique ways at incidents such as structure fires, building collapse rescue incidents and vehicle extrications. To use these saws effectively, however, we must also keep abreast of advances made recently in the design and manufacturing of the reciprocating saw blades themselves.

The most important action a fire department can take to dramatically improve the capabilities of its reciprocating saw is to stop using consumer-grade blades and begin immediately to only utilize break-resistant, bi-metal blades specifically designed for the rugged use and abuse of fire-rescue applications. This new family of super-heavy-duty blades, commonly known as demolition blades within the industry, are such a vast improvement in what we have used in the past that they make the standard hardware store variety saw blades obsolete.

Manufactured by companies such as DeWalt, Milwaukee and American Saw & Manufacturing Co., the demolition blades reduce tang breakage, a common problem with lightweight consumer-grade blades. The new rescue blades also bend rather than snap or break and minimize tooth chipping compared to standard blades.

Bi-metal demolition-type blades are sold to professional contractors through industrial supply houses and are now even available through nationwide outlet stores such as Home Depot and Lowe’s. The cost per blade is more than a consumer-grade blade but the advantages and capabilities of these blades far outweigh their cost factor. Fire/rescue teams should not use anything but industrial-grade, bi-metal demolition reciprocating saw blades specifically designed for fire and rescue applications. Contact information on three manufacturers of demolition-type rescue blades is offered at the end of this article.

Bi-metal reciprocating saw blades have actually been manufactured for many years: the original bi-metal blades were first introduced in the 1960s. These blades work so well for rescue applications because of their special rugged construction. They consist of two types of metal (thus the term bi-metal): a high-speed steel cutting edge that is welded to a strong, flexible spring steel back.

The thin high speed steel edge contains all the teeth that do the cutting while the thicker main body of the blade, called the back, is specifically designed to help resist breakage during sawing operations.

Blade Thickness Matters!

Another difference with the new demolition blade is apparent when one compares the standard blade to a new fire-rescue blade. Most hardware-store-variety reciprocating saw blades are .035 of an inch thick or less. Blades this thin may be acceptable for weekend jobs around the house, but they fail miserably for fire-rescue applications.

The new TORCH and AX blades from Milwaukee, for example, are .042 of an inch thick. Both the DeWalt and the Lenox line of Demolition blades are .062 of an inch thick. When using these rescue blades, you will feel more resistance because the thicker blades is actually cutting more metal. You simply increase your pressure on the tool to offset this resistance.

Manufacturers produce blades with different numbers of cutting teeth because of the various types of materials that must be cut through. The number of teeth along each inch of the blade is the referred to as the blade’s tooth-per-inch (tpi) rating. A high tpi number such as 18 or 22 indicates a fine-tooth blade, one with many small teeth along its cutting edge. This blade is used by builders or contractors to make detailed cuts in thin metal, plastic or laminate materials.

Fine-tooth 18 or 22 tpi reciprocating saw blades serve no useful purpose for vehicle rescue applications. The cutting teeth are too small and too fine for the thickness and layering of metal being cut through at extrication scenes. An 18-tpi blade will not last long enough at a crash scene to perform effective cutting. Using a blade that is too fine for the job also causes it to cut more slowly and to wear out rapidly.

For the majority of vehicle rescue applications, a medium tpi blade is the best to use. Extrication crews should consider standardizing on using the new bi-metal blades rated between 10 and 14 tpi.

To make it even easier to standardize on blade choice for rescue applications, manufacturers now produce "variable tooth" blades. These are very versatile for our vehicle rescue applications. A typical “vari-tooth” blade has a rating of 10/14 tpi. This means that throughout the length of the blade, the tpi changes back and forth from the finest setting of 14 tpi to a coarse setting of 10 tpi. These variable-tpi blades are the most efficient all-around fire rescue blade available. If you only had one blade style to stock in your inventory for vehicle rescue, they should be variable tooth 10/14-tpi blades.

To cut through wood such as a tree limb or structural lumber, a coarse-tpi saw blade with a tpi of 6 or less would be used. I have also used 6-tpi blades for cutting sheet metal along the side panel of a vehicle. With a 12-inch-long, 6 tpi blade, I can completely cut out the "third door" of a two-door vehicle along with the B-pillar. This aggressive cutting allows the entire sidewall, B-pillar and door to open on the front door’s hinges.

Cutting vehicle metal with a blade designed for wood, however, causes a lot of saw vibration and is noisy. But with a well-prepared and properly trained rescuer, it results in an aggressive attack that will quickly open up the entire side of a damaged vehicle. This is not the blade of choice for tubular metal, pipes or even narrow roof pillars. For sidewalls or the base area of a B-pillar however, the 6-tpi blade is an exciting alternative. Grab hold, hang on and be impressed!

Besides the routine metal cuts through vehicle components such as roof pillars with 10/14-tpi blades, a reciprocating saw can be very effective in totally removing a vehicle’s windshield. When cutting laminated glass, a coarse-tpi blade is better. Use a 6-tpi or a variable tooth 10/14 for best results on the windshield. The finer teeth of a straight 14- or 18-tpi metal cutting blade dulls quickly as the glass is cut. Any reciprocating saw blade that is used to cut out a windshield should be discarded after the windshield evolution is completed because the cutting edges of the teeth will be significantly dulled.

Recommended Lengths For Extrication Blades

Crews using reciprocating saws for any of a wide variety of fire-rescue applications should stock three basic lengths of saw blades in their inventory. The shortest blades should be six-inch-length units. These would be used only when there is limited clearance or when a longer blade cannot fit into an opening.

The most effective length blade for all purpose vehicle rescue applications is the eight- or nine-inch blade. Fire departments should make the eight- or nine-inch blade their standard rescue attack blade and pre-blade their saw with this length. This versatile length blade cuts best through the multiple layers of material found in vehicles today; thick rear roof pillars, side B-pillars, door panels, etc.

For unique circumstances, rescue teams should stock a minimum number of 12-inch-length blades also. These special-purpose blades are useful when cutting through some thick object such as the base of a B-pillar on a full-size sedan, the entire sidewall panel of a two-door coupe or the side of a van. With the longer length blade, it is possible to cut through all layers at the same time. The protruding end of this blade, however, may be too long to be used near a patient. There is one more caution when using this long length blade. If a 12-inch blade is used to cut through a thin wall material, the extra length of the tip causes the blade to "wag" back and forth. This wagging causes the material being cut to also vibrate and reduces the cutting efficiency of the saw.

For every quantity of reciprocating saw blades that a fire department stocks on its rescue vehicles, the majority of them should be eight or nine inches in length. We should always have available two or three blades that are six inches in length and another two or three that are extra-length 12-inch blades.

If I could only have 12 saw blades with me on a rescue call, I’d want eight of them to be eight-inch, 10/14-tpi blades. I’d want two more to be 12-inch, 6-tpi blades and the final two to be 6-inch 10/14-tpi blades. This selection would be the basis of my saw blade starter kit.

No Blade Lubrication During Vehicle Rescue!

Cutting through certain hardened metals with a reciprocating saw can produce small sparks. This is due to the overheating of the metal being cut. Blade manufacturers instruct industrial saw users to lubricate saw blades with cutting oil when using a reciprocating saw. The manufacturers' engineers explain that lubrication at the point of cutting makes for an easier operation and provides a longer blade life.

Firefighters, seeing these recommendations, have for years lubricated reciprocating saw blades at vehicle rescue incidents. When we used actual cutting oils, we found that the friction of the saw blade as it cuts produced a smoke that smelled like something was burning. This was not good for a conscious patient to smell while trapped inside a vehicle. So the "cure-all" solution was introduced: soapy water. It doesn’t smoke, it’s cheap and it appears to work.

Field research conducted by this author has determined that lubrication of a reciprocating saw blade during vehicle rescue incidents does not noticeably improve cutting speed or the efficiency of the cutting action. In addition, applying soapy water from a squeeze bottle ties up a rescuer that could be better put to work doing something productive. Without lubrication, you do get additional heat around the teeth, which softens them. Blades will have to be changed more often, but with the new saws having a keyless chuck, a blade change takes less then three seconds to complete.

Under fire-rescue applications, I recommend NOT lubricating the blade of a reciprocating saw. We are not interested in saving money by prolonging the life of the blade as the owner of a machine shop would be. We’ll throw our used blades away when we return to quarters and will come to the next extrication call with a fresh blade installed in the saw. Don’t waste your time or your personnel lubing a blade!

Lubrication is recommended, however, for the reciprocating saw itself. Tools used under real-world rescue applications can quickly accumulate foreign materials inside the working components of the saw especially at the blade clamp area. Periodic cleaning, inspection and lubrication of the saw at an authorized service center will increase the reliability of the tool and prolong its useful life span.

Proper Cutting Procedures

Here are some general guidelines to consider when working with a reciprocating saw at fire-rescue incidents:

· Hold the saw firmly with both hands, but only by the insulated gripping surfaces, when performing a cutting operation. Unintentional contact with a "live" energy source, such as a wire of the vehicle’s electrical system, can energize the exposed metal parts of the entire tool. This will cause shock to the saw operator if your hands are incorrectly placed on the bare metal of the tool.

· If you have a variable-speed reciprocating saw, select the proper speed for the material being cut. As a general rule, with harder metals such as cast door hinges or Nader pins, a slower saw speed will be more effective. A lower speed setting, approximately 1,500 strokes per minute, is good for most metal cutting. Increasing the motor speed to full does not get a significant improvement in cutting speed. Slowing the blade speed down increases blade life and does not reduce overall cutting time.

· With a variable-speed feature on your saw’s trigger, "feather" the speed to give you the best performance. If you have to work only at the high-speed setting on your saw, adjust your grip to a moderate pressure on the material being cut. Relaxing the pressure slightly will actually allow the blade to cut faster and to last through the entire cutting action.

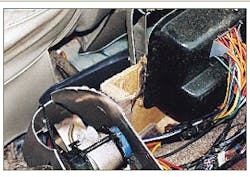

· Whenever possible, the saw shoe must be held firmly against the material being cut. This will prevent the saw from jumping or vibrating and will minimize damage to the blade’s teeth. Not keeping the foot of the saw in contact with the material being cut is the number one reason for ineffective reciprocating saw cutting at crash scenes.

· Do not force the tool or bind the blade. This diminishes battery life on cordless reciprocating saws. Create a rocking action by moving the body of the saw up and down as you cut while the foot remains in contact with the material being cut. Maintain the appropriate pressure against the material for the most effective cutting action.

· Protect yourself and your patient during the operation of the saw. Rescue personnel should don appropriate personal protective equipment (PPE), including safety glasses or goggles. Patients should have "hard" protection such as a KED or XP-1 immobilization board placed between them and the cutting blade.

· Blades are hot immediately after operation. Do not grab a used blade by the working end. Open the blade clamp and allow the blade to fall out of the end. Burns on fingertips are painful!

· Avoid accidental saw starting. Be sure the safety switch is in the locked position before making adjustments to the tool, inserting a fresh battery pack or changing the saw blade. Store your saw with the safety in the "locked" or "on" position.

· Do not operate a corded or cordless power tool in an explosive atmosphere. Power tools create sparks internally and externally, which may ignite dust or flammable vapors present in the area.

· For teams working with the newer generation of cordless reciprocating saws, remember to protect the exposed battery terminals from contacting any metal objects such as nails or screws. Metal across the terminals will short the battery out and may cause sparks, burns or a battery fire.

Blade Manufacturers Contact Information

Bi-metal "Demolition" blades are available from: DeWALT Industrial Tool Co. 701 E. Joppa Road Towson, MD 21286 800-892-4776 www.dewalt.com

Bi-metal "The TORCH" and "The AX" blades are available from: Milwaukee Electric Tool Corp. 13135 West Lisbon Road Brookfield, WI 53005-2550 414-781-3600 www.mil-electric-tool.com

Ron Moore, a Firehouse contributing editor, is a battalion chief and the training officer for the McKinney, TX, Fire Department. He also authors a monthly online article in the Firehouse.com “MembersZone” and serves as the Forum Moderator for the extrication section of the Firehouse.com website. Moore can be contacted directly at [email protected].

Series Links:Part 1 | Part 2 | Part 3 | Part 4 | Part 5