Understand 18-volt cordless reciprocating saw features & functions.

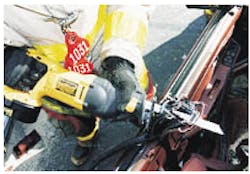

Subject:Cordless Reciprocating Saws, Part 1Topic:Features of cordless reciprocating sawsObjective:Understand 18-volt cordless reciprocating saw features & functionsTask:Compare DeWalt and Milwaukee 18-volt cordless reciprocating saws for vehicle rescue tasksReciprocating saws are rapidly gaining in popularity among fire and rescue teams worldwide. Their acceptance prompted me to begin a research project to explore the capabilities of the newest generation of reciprocating saws, the cordless models. Currently, cordless reciprocating saws are manufactured by Milwaukee Electric Tool Corp. of Brookfield, WI, and by DeWalt Industrial Tool Co. of Hampstead, MD.

Through this series of University Of Extrication columns, we will look at the features of the saws themselves, explore various battery power supplies that are available, and learn about proper saw blade selection and use. Later in our series, we’ll report on reciprocating saw endurance tests conducted during more than 18 months of real-world fire service testing. In the final installment, we’ll introduce the newest generation of cordless reciprocating saws, those operating on 24-volt power supplies.

We begin our series by comparing features of the two current brands of cordless reciprocating saws. Milwaukee manufactured the first reciprocating saw in 1952 and coined the popular term “Sawzall”, a registered trademark of the Milwaukee Electric Tool Corp. In this article, we’ll look at its newest cordless saw, the 18-volt Power-Plus Sawzall, model 6516-21. The other cordless saw we’ll study is the DeWalt 18-volt model DW938.

The saws are similar in many ways, though it isn’t the ways the saws are the same that interests fire rescue personnel - it’s their differences. As a result of our intensive evaluation process, we’ll present to you both the strengths and the weaknesses of each tool in areas that are vitally important to fire-rescue personnel.

Tool weights were each similar with the DeWALT weighing approximately seven pounds with a battery and the Milwaukee saw and battery weighing 8 1/2 pounds. The DeWalt is 17 inches in overall length while the Milwaukee is 18 inches.

Reciprocating saws get their name from the fact that during operation, the saw blade moves back and forth to cut the material. This distance, known as the saw’s stroke, measures 7/8 of an inch on the DeWalt and an inch with the Milwaukee. Essentially a saw’s stroke determines that portion of a blade that will be doing the most aggressive primary cutting.

Along with a saw’s stroke is another important measurement referred to as its strokes per minute (spm). The saw blade travels one complete cycle back and forth as it cuts through the material. The number of these complete cycles per minute is the saw’s spm. The DeWalt saw has a variable rate of 0-2,800 spm as controlled by the squeezing of the trigger. The Milwaukee unit’s trigger control allows for a 0-2,000 spm. A reciprocating saw with a variable speed trigger runs faster as the trigger is pressed more fully. Both tools feature a safety lock trigger to prevent accidental saw operation. As a safety feature, there are no provisions on either saw to lock the trigger in the ?on? or ?run? position.

The blade clamp holds the blade in the working end of the saw. Reversing a blade in the clamp of a reciprocating saw may be necessary for unique situations where there is very limited access for cutting. Although the blade is reversible in both saws tested, meaning it can be positioned with the teeth facing up or down, there are important differences in the method by which the saw blade is secured in each saw.

Both tools use a keyless chuck design, which is a real convenience for fire-rescue operations. The Milwaukee design, called the Quik-Lok Blade Clamp, is a barrel-shaped twist design located between the end of the saw and the saw’s shoe. As the barrel is rotated, it releases its grip on the saw blade. When the operator lets go, a spring return tightens the chuck into the blade in the saw.

DeWalt’s lever-action keyless blade chuck operates by raising or lowering a lever mounted on the outside of the saw. Lifting the lever releases the blade clamp, lowering the lever secures the blade in place.

The material being cut is contacted by the shoe of the reciprocating saw. With a fixed mount shoe, the saw uses only the nearest inch of the blade, an area which wears out long before the rest of the blade has even cut any material. By designing an adjustable shoe feature, Milwaukee lets the saw operator use more of the saw blade. With an adjustable shoe, the operator moves the shoe further from the end of the saw. With the shoe adjusted to any of its three extended positions, different teeth of the blade contact the material being cut. With an adjustable shoe, it is possible to use each saw blade much more efficiently.

While the shoe on the DeWalt saw is not adjustable, it does pivot back and forth to match the angle of the saw against the material being cut. The Milwaukee shoe, although with adjustable positions, is fixed at a permanent angle.

The 18-volt batteries that power the saws are attached to the base of each saw’s handle. DeWalt uses a prong-type design that inserts up into the inner hollow of the handle base. Milwaukee features a slide rail design allowing the battery to slide into and out of the handle base on large alignment grooves. Both saws use a high-impact polycarbonate plastic to mold the body of the saw.

University Of Extrication Product Review

At first glance, these two saws appear similar in all their basic features and operation, differing only in their color and shape. There are no major design flaws or unusual quirks with either saw. A fire-rescue purchaser would be satisfied with either tool in the rescue inventory. Through our endurance testing and actual fire rescue applications, however, the weaknesses and strengths of each saw became apparent.

Our work with the DeWalt saw continues to be an ongoing learning experience. The company is continually upgrading and modifying its product as evident during the last 18 months, improving with each new version of the tool. The current model DW938 saw is much improved over earlier models.

The slow and cumbersome manual chuck key feature found in the original 1998 version of the DeWalt 18-volt saw has been replaced by a keyless lever chuck. This lever-action design performed significantly better under our rescue applications than the twist barrel keyless chuck design of the Milwaukee tool.

We were able to close the DeWalt blade clamp even when debris was present inside the clamp. Dirt, plastic and wood shavings, mastic glue from roof pillars and cloth from roof headliners continually caused the Milwaukee twist barrel to fail. The barrel spring return either would not release the dirty blade or would not accept a replacement blade because it could not fully clamp down onto the blade itself. This was the most serious challenge encountered with the Milwaukee product.

Releasing the 18-volt battery while wearing fire rescue gloves was difficult with the DeWalt saw. All rescuers involved in our field testing preferred the large release button design of the Milwaukee Sawzall battery. These large buttons released easily every time while the tool operator could keep their rescue gloves on. DeWalt was aware of the problem with their small battery release buttons and moved to address it. DeWalt’s latest generation of 18-volt batteries, the XR2 NiCad model, now have improved release buttons. The new battery’s performance is comparable to that of the Milwaukee.

We did experience a battery release problem with one Milwaukee battery. After being secured in place on the saw, this battery would slide forward from its’ position when the saw encountered severe vibration during cutting. The problem turned out to be a defective battery, which was quickly replaced by Milwaukee. All Milwaukee batteries currently being tested remain secure in the handle during use and abuse.

In Part 2 of our series, we’ll attack the myths that surround rechargeable batteries and look at alternative power sources for cordless reciprocating saws.

| DEWALT | MILWAUKEE | |

|---|---|---|

| Weight of saw with battery | 7 pounds | 8 pounds |

| Length of saw w/o blad | 17 inches | 18 inches |

| Stroke length | 7/8 inch | 1 inch |

| Strokes/minute | 0-2, 800 spm | 0-2,000 spm |

| Trigger safety lock feature | Yes | Yes |

| Reversible blade capability | Yes | Yes |

| Keyless chuck type | Lever type | Twist barrel |

| Shoe/foot adjustable | No (flexible) | Yes (3 positions) |

| Battery type | 18 volt | 18 volt |

| Housing/handle | Plastic | Plastic |

| Battery shoe design | Prong inserts into handle base | Slide rail design |

| Battery release button | Twin buttons on sides of battery | Twin buttons on sides of battery |