Understand Volvo's Side Impact Protection System.

SUBJECT: Side Impact Protection System (SIPS)

TOPIC: Volvo (SIPS) Technology

OBJECTIVE: Understand Volvo's Side Impact Protection System

TASK:Identify components and function of Volvo SIPS

Though only one in four crashes is a side or T-bone collision, this type of accident is responsible for one out of every three highway deaths. According to the latest statistics from the National Highway Traffic Safety Administration (NHTSA), side-impact collisions are now responsible for over 31% of all automobile fatalities.

All 1997 model year automobiles currently being sold in the United States must meet new federal side-impact standards. Most auto manufacturers incorporate Side Impact Protection Systems (SIPS) into the structure of their vehicles. Rescue and EMS personnel must be aware of the components of SIPS to fully understand the impact this technology has on vehicle tasks and mechanisms of injury for occupants.

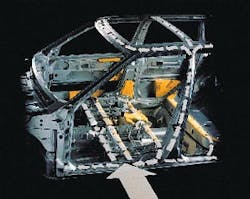

The innovator in this improved structural design system is Volvo. The Volvo side-impact system consists of specially designed structural members of the passenger cabin, reinforcement inside the doors and special side-impact airbags mounted along the outside edges of the front seats. This training notebook looks at the SIPS structural components. (SIPS airbag operation is addressed separately.)

Transversely mounted high-strength tubular and steel braces run across the floor of the Volvo beneath the front seats. These tubular braces are under the front seats and use a structural member between the seats to help transfer impact focus away from the occupants. In the front-wheel-drive 850 models, that structural member is a high-strength steel box designed for the purpose. In rear-wheel-drive 960 models, that structural member is the carefully reinforced driveline tunnel. In addition, there are other transverse reinforcements to the floor following the contour of the rear seat as well as the profile of the steel floor.

The central B-posts are reinforced and attach at broadly reinforced sections of the floor and at the roof. The roof of each 850 model is attached to the car's one-piece body side stampings using a continuous laser welder for a single, high-strength weld. Rescuers should note that all Volvo roof posts and the B-posts are essentially double or triple layers of steel throughout. In addition, the center of the roof is reinforced by a transverse structural member which ties the top of the B-posts together. Across the roof, these box-shaped steel members act as roll bars.

Volvos have anti-intrusion bars built into all four doors. These strong tubular steel bars are welded inside the door frames to add strength. The contour and surface of the door panel has also been designed to minimize intrusion and chance of injury to occupants. The door hinges have a locking tab which helps to hold the door in place even if the welds holding the hinge to the roof post should be sheared in an accident.

The door sills of all Volvo models have a large cross section for both side-impact protection and for absorbing longitudinal impact forces. The body structure gains additional strength through the use of continuous laser welding on the entire roof on the 850-series models, rather than individual spot welds. All Volvo models gain torsional strength through the use of hot adhesives to bond the windshield and rear window glass to the body structure, in effect making these pieces of glass structural members.

The SIPS design transfers crash energy to the opposite side of the car via the special reinforced cross members in the floor and roof. Specially designed and reinforced roof posts at the front, center and rear of the passenger compartment transfer forces to the cross members while maintaining their own structural integrity.

Task: Identify components and function of Volvo SIPS (1996 or newer model Volvo)

- Reinforcement of B-posts.

- Reinforcement of roof support members.

- Reinforcement of floorboard areas.

- Reinforcement of side door "collision beam" structure.

- Installation of SIPS side-impact airbags in front seat.

Ron Moore, a Firehouse? contributing editor, is a battalion chief and the training officer for the McKinney, TX, Fire Department. He also authors a monthly online article in the Firehouse.com "MembersZone" and serves as the Forum Moderator for the extrication section of the Firehouse.com website. Moore can be contacted directly at [email protected].