In the last installment of the Apparatus Architect (May 2002), we reviewed several concepts to improve the safety and design of the front bumper area of pumpers. Front-end and intersection accidents are quite common with all types of apparatus. With a little thought during the design process, the integrity of the frontal area of your new pumper can be greatly enhanced as well as improving the safety for your personnel riding in the crew area.

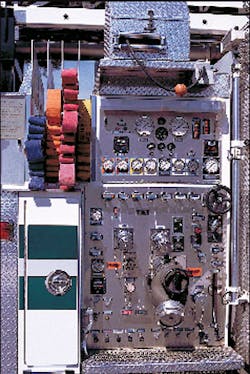

With this article we will discuss the layout and design of the pump panel area and the associated plumbing that is required for the engine company to deliver its rated capacity through pre-connected attack lines and appliances.

Once your apparatus committee has determined the basic fire pump and water tank size, the job of designing the pump panel and piping configuration has just begun. Many departments will carefully discuss the merits of a 1,500-gpm vs. a 1,750-gpm pump or a 750-gallon booster tank vs. a 1,000-gallon booster tank. Whether you are attempting to "buy up" one size or have a repeat performance from an existing design, the pump operator's panel is one of the most important yet overlooked areas regarding engine company design.

The engine chauffeur/pump operator is one of the most important personnel who operate on the fireground. This individual is responsible for obtaining a continuous and reliable water supply and for insuring that the first attack line gets water when called for by the engine company officer. The layout and design of the pump panel is one of the most important pieces of real estate on the apparatus.

While most manufacturers have a standard pump panel design, it is important for the fire department's apparatus committee to specify the location of certain pump instrumentation, suction and discharge valve controls and other components. Unlike buying a car, where you can choose the exterior and interior colors but have no choice on the dashboard layout, the pump panel design on an engine company should be laid out in a logical fashion that meets the operational characteristics and standard operating guidelines of your department.

During a recent major trade show, we took the opportunity to review and compare the layout of many manufacturers' pump panels on units that were on display. It became apparent that everyone had a different idea as to how the panels should be designed and most importantly the color and position of major controls were in different locations on just about every unit. When manufacturers' representatives were asked why certain designs were built in the fashion that they were, the most common response was that the "engineering determines where the controls are placed." Now, if the manufacturer that you have chosen to build your apparatus happens to be a firefighter or has some experience in operating fire pumps, then you have a fairly good chance of getting a pump panel that is laid out in some logical fashion. However, you may be better suited to spend some time in reviewing the proposed layout of your pump panel and discussing this design with the manufacturer at the time of the pre-construction conference. One of the inherent problems of designing fire apparatus is that the manufacturing sector has probably never been to a fire and the firefighters designing the apparatus have no appreciation for the manufacturing sector. This is truly a sad state of affairs.

The first consideration may be the position of the pump panel at the side, top or rear of the apparatus. While we will not enter into the debate regarding side-mount vs. top-mount designs, the overall layout must fit into the department's tactical operations. For example, if your department operates with multiple pre-connected lines in a crosslay or Mattydale arrangement, then these lines must be located low to the ground with the valve control handles positioned in a straight row from front to rear to match the position of the respective attack line. The Syracuse, NY, Fire Department has operated engine companies with four pre-connected Mattydale crosslays since 1972. Over the years, their pump panels have incorporated several subtle changes like the position of the master gauges and engine governor controls to make the driver's job easier when operating on the fireground.

A word of caution: four-door commercial chassis pumpers with side-mounted pumps seem to work well. Two-door commercial chassis pumpers with top-mounted pumps seem to work well. When departments start to incorporate top-mounted pumps with four-door commercial cabs, wheelbases climb over 260 inches and make these units difficult to maneuver, particularly in a rural setting. The industry standard for top-mounted pump walkways is 18 to 22 inches and that spreads the wheelbase that much more.

The position and size of pressure gauges should be given consideration by the apparatus committee. Master gauges are generally offered in 41/2-inch and six-inch sizes with various pressure ranges. The bigger gauges offer a larger scale to read the intake and discharge pressures, particularly when combined with gauges reading in the 0 to 400 psi range in place of the more common 0 to 600 psi range. This is particularly important with the smaller individual pressure gauges that are used on discharges with pre-connected attack lines.

The position of the gauge on the pump panel is important to enable the operator to clearly view the gauge when the attack line is deployed. If you cannot read the gauge in the daylight in good sunlight, don't expect the pump operator to be able the read the 21/2-inch gauge at 2 o'clock in the morning under heavy fire conditions.

If your department operates with Mattydale-style crosslays, consideration should be given to a design which allows for the beds to be no more than 64 to 65 inches above the ground. We have probably all seen pumpers where the crosslay beds are so high that you must stand on the pump panel step in order to reach the hose and nozzle.

Likewise, it is important to specify the size and length of hose that will be loaded in these beds to enable the beds to be the proper width. In addition, you may wish to specify that the chicksan swivel be located toward the edge of each bed or that the discharge terminate immediately below each bed. At this point, you may want to add speed lays - be careful. Speed lays add an additional 15 inches minimum to the wheelbase of the apparatus.

Pump panels with color-coded intakes and discharges have been required by the National Fire Protection Association (NFPA) 1901 standard for some time. Some fire departments have employed different-color hoses and nozzles to match up with the colors on the pump panel. Another concept is to design the pump panel and plumbing to provide for multiple discharges with pre-connected lines attached to each discharge. In some areas of the country it is not uncommon to see engine companies with six to eight pre-connected attack lines in sizes ranging from 13/4 to three inches with lengths ranging from 100 to 400 feet. Bulk hosebeds can supply the necessary hose to make up lines which are required when hose stretches are longer than 400 feet.

In order to develop their rated pump capacity, engine companies need to be designed with an adequate number of gated suction or intake lines to supply the fire pump with water. With the use of four-inch and five-inch large-diameter hose (LDH) many departments have become reliant on a single hoseline for water supply. Large-diameter intakes can be positioned on both the left and right side pump panels as well as the rear under the hosebed.

Consideration should be given to using the right side pump panel for the large-diameter intakes to keep the left side clear of hoselines for the pump operator. Using a power-operated valve with an air bleeder and manual override allows the pump operator to control the intake without having to run around the apparatus.

Externally mounted manual valves are less expensive, but generally are difficult to control and "gate back" when needed. Either style of valve requires an intake relief valve, which will protect the fire pump and hoselines from water hammer. Some departments have strategically limited themselves by loading the hosebed with LDH and placing two-inch pre-connects above the pump panel. That would be like a carpenter going to work with only a hammer and a square. Consider your pumper to be a giant tool box - the more tools you have in the box, the better able you will be able to meet the diverse firefighting challenges ahead.

Each engine company should be capable of handling at least two large-diameter intake lines through gated intakes. Pumpers which are rated for 1,250-gpm and more will generally require dual lines to produce their rated pump capacity, depending upon the length of the hose lay and the residual pressures. Intake lines should be fitted with the proper adapters to accept the supply line that is normally carried by the engine as well as an additional line of the same size.

If your department operates with other engine companies which carry different hose sizes, then you should equip your pumper with the necessary adapters and fittings to make any necessary connection. All adapters and fittings should be color coded for size and appropriately marked where they are carried on the apparatus.

While it may be desirable to incorporate a Class A or B foam system into your next pumper, the space required for these systems may require some careful planning. For example, if you have chosen a combination A/B foam system that requires dual tanks, inquire with the manufacturer's engineering department just how much room this will occupy on the pump panel and how the foam system controls can be easily integrated into the overall pump panel design.

The inclusion of a compressed air foam system (CAFS) will certainly require additional space on the panel and consideration needs to be given to making some of these components accessible for maintenance and repairs. While short-length pump panels will help in keeping the overall length of the vehicle down, panels with excessive controls are difficult to operate and hide components which are often impossible to access for routine service.

A final consideration in the pump panel area should be the presence of adequate lighting for both the pump panel itself and area or scene lighting. The pump panels on both sides of the apparatus should be illuminated to provide sufficient lighting for the panel instruments, step areas, discharge and intake piping, as well as the top area above the pump. This is especially important if the apparatus is equipped with crosslays or a top positioned deck gun. Depending upon the width and layout of your pump panel, the manufacturer's standard lighting configuration may not sufficient to illuminate all of the panel area.

There are many examples of poorly laid out and designed pump panels on engine companies that are currently in service. One of the greatest challenges for the apparatus committee is to carefully review the panel layout for your next pumper and have it designed to meet your operational and training needs and not just throw all of the components in this small space. The engine company chauffeur has one of the most important jobs on the fireground and anything that we can do to make this person's job easier and safer will greatly enhance the overall operation.

In the next installment of the Apparatus Architect we will discuss the body and hose compartment area on the pumper and what can be done to enhance these components.

Tom Shand, a Firehouse