Ballam: A Fire Truck Committee Is Born

My department has formed a truck committee and our first meeting will be later this month. The five-person committee, of which I am one, will be tasked with replacing our front-line engine that’s more than 20 years old.

We acknowledge we have a lot of work to do between now and when we hope to take delivery of it in a couple of years. Our first meeting is going to be mostly brain storming to figure out our hopes and dreams for this new apparatus.

And, I have to say, it a little exciting. It’s not often a small rural department like mine has a new apparatus.

This isn’t my first truck committee, but it will certainly be different. We have different leadership, different funding mechanisms, different members, and a lot of other different needs.

Fortunately, most manufacturers have plenty of experts and lots of information to help guide us in our decision making process. And I, for one, plan to use a lot of it. I’ve been writing about fire apparatus for more than 15 years now and visited most of the major manufacturers’ plants nationwide, but I’ll be the first to admit that I don’t know everything about fire apparatus. I’ll share what I know, which is a fair amount, but I want to hear from the folks that live and breathe fire apparatus daily.

From my experience, most manufacturers are responsive and will help connect the dots as departments work through the process of making their desires and needs work within their budgets. Not every department has unlimited resources to buy everything their hearts desire. Most of us, including my department, will have to compromise – wants and needs versus budget consideration.

We’ve all seen those “pimped out” 10-crew member cab apparatus seemingly with more gold leaf than body paint color and blinky lights and Roto-Rays and gizmos and… you get the picture.

On the other end, there are many good, solid apparatus built on commercial cabs and chassis with stock painted wheels and just the right number of lights to be compliant. They’re good trucks too.

I’d bet there’s little argument that the mission of every apparatus is essentially the same, bring water, tools and personnel to emergency scene to resolve the incident. Granted there’s a lot of variations on the theme, but the theme remains throughout, even aerials and tillers which are tools in and of themselves.

While our committee is still in its conceptual stage, I am sure what we’re looking for, and will ultimately end up with be somewhere in the middle of the two ends of the spectrum.

Our chief has some good ideas already and I am sure each of our truck committee members has ideas too.

Buying a new engine is like planning a vacation for some of us. We can dream and fantasize until our hearts are content in the initial stages. As the committee work progresses, and we get close to seeking bids and proposals, reality will set in and the real decisions will be made.

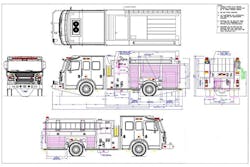

It’s likely we’ll be headed for a modified pumper/tanker combination on a custom cab and chassis. In addition to our front-line engine, we have a secondary tanker, built in 1983 with a gasoline engine and a stick shift with a funny little red button on the side near the knob. Some of the “kids” in our department have no idea that it’s for the electric two-speed axle and, consequently, can’t, won’t and probably shouldn’t drive it. Don’t get me wrong, I love the young guys on our department. We couldn’t operate without them. That’s why we need to think about apparatus they can operate comfortably. It’s likely I’ll be “retired” from the volunteer fire service before this new apparatus is retired, so we’ve got to think about the next generation too.

So, our new apparatus will likely be a custom cab and chassis pumper with a big tank, maybe 2,000-gallons, on a tandem axle chassis. That will allow us to retire our two oldest apparatus. Our front-line tanker is a 2003, carrying 1,800-gallons with a 1,250-gpm pump and a Class A foam system. It works nicely as a tanker with electric dump valves on three sides and as a pumper with pre-connected crosslays and SCBAs mounted in a back compartment.

As our day-time response crew diminishes, seemingly yearly, we’ve recognized the need to have apparatus that will carry a significant amount of water for initial attacks as the chances of rolling either of our tankers simultaneously with the engine, with full crews, is slim to none.

From that foundation, our committee will be looking at other important aspects, like number of persons in the cab, top- or side-mount pump panels, or something completely different. At one of the trade shows last year, I saw a completely electronic pump panel that was stowed in a compartment in the middle of the apparatus. That was pretty neat and saved a lot of compartment space. As the mission of fire apparatus evolves, less fires and more of everything else, it might make sense to think about reducing the space devoted to pumping.

One member of our committee, who is an elementary school principal and a heck of a firefighter with lots of experience, readily admits he knows virtually nothing about the truck specifications, like engine sizes, weight and gear ratios and the related mechanical things. We have other guys on the committee who know that kind of stuff, but I’d rather leave that stuff to the engineers who will be designing what we will ultimately be purchasing. They’ve got the computers and the brains to put that stuff together and I see no reason not to use them. We know enough about apparatus and trucks to know if they’re way off, which I seriously doubt would ever happen. After all, they want to stay in business. Years ago, I heard the late Bob Barraclough, a renowned apparatus guru, say “it’s hard to hide a bad fire truck. Fire chief’s talk to each other a lot.” And I know that to be true.

I’d also like to think about ways to keep people off the top of the apparatus. Hydraulic ladder racks, remote controlled deck guns, lower hose beds, through-the-tank ladder compartments, fold down steps built into compartment doors all help keep firefighters closer to terra firma and, therefore, safer.

There will be lots for our committee to talk about and lots of research to be done. I’ll keep posting progress as we continue.

It’s going to be fun.