Every firefighter has wondered about the potential positive outcomes of reaching an emergency scene earlier. What might have gone differently if the crew had one more minute? Or just 30 seconds more?

Obviously, shorter response times can’t simply be willed. Most variables are beyond control. These include traffic density and flow, terrain, weather conditions and site accessibility.

Even under the best conditions, quickness must be balanced by safety. Toward that end, National Fire Protection Association (NFPA) 1901, Standard for Automotive Fire Apparatus, specifies maximum top speeds for fire apparatus and other emergency vehicles. Specifically, apparatus with 1,250-gallon combined water capacity and gross vehicle weight rating (GVWR) over 50,000 pounds shall not exceed 60 mph; apparatus over 26,000 pounds shall not exceed 68 mph.

So, faced with restricted maximum driving speeds, how can fire departments shave crucial seconds from response times? Growing attention to tire pressures, vehicle stability control systems and other vehicle optimizations helps. Another answer is taking a deeper dive when it comes to apparatus engine power.

For many apparatus specifiers, the rating that matters most is horsepower. This is understandable because horsepower rating is the popular, accepted short-hand for engine power. But horsepower won’t help emergency crews get to the scene faster. Torque will.

One familiar (though overly simple) illustration of torque is the opening of a fire hydrant. Applying muscle force to the end of the hydrant wrench creates torque on the valve cap, causing it to rotate. In an engine, combustion in each cylinder produces the “muscle” that drives piston and rod to rotate the crankshaft, which, down the power train, forces the drive wheels to turn on the pavement. It’s this force that allows the heavy apparatus to overcome resistive forces of inertia, friction and gravity and begin moving. This is low-end torque, meaning the rotational force produced by the engine at the low end of its rpm range. More low-end torque means faster acceleration. Faster acceleration means less time to reach safe driving speeds up to the allowable maximums.

The engine’s horsepower output can be calculated at the moment when the apparatus begins to move, but it is a meaningless number (torque x rpm ÷ 5,252) that has no bearing on acceleration. Horsepower – or more appropriately “high-end torque” – factors into maintaining driving speeds in top gears, but because speeds are capped, fire apparatus engine horsepower is often over-specified.

Acceleration

The importance of acceleration to firefighting is evidenced by another section of NFPA 1901 that mandates “the apparatus shall be able to attain a speed of 35 mph within 25 seconds on a level road.” And it’s low-end torque that will make the difference between meeting the NFPA standard and providing the best possible response time.

Specs impacting acceleration like rear-axle ratio, transmission gear ratio, torque converter and tire size typically are called for in apparatus RFQs. Truth is, though, these have by and large reached parity in the industry, especially where suppliers like Allison have become the default standard. All emergency apparatus will meet the minimum NFPA 1901 acceleration standard.

How can fire departments make better informed decisions about diesel power as it best serves emergency response times? This turns out to be fairly simple, and well worth the time investment.

Engine Options

First, determine a rough set of standard specs – horsepower, peak torque, tire size, transmission configuration, etc. Next, run an Allison SCAAN calculation with different engine options. The SCAAN program calculation is widely accepted as the standard in the industry. Note that the results are simulations and don’t take into account turbo lag, engine reaction time and other real-life factors that affect acceleration. In addition, rotational inertia of the engine, tires and wheels are typically estimated for these simulations. With that in mind, SCAAN results should not be your only tool to evaluate your new purchase, but the results will provide a clearer picture of the capabilities of the engines in your considered set. Then, because computer simulation cannot account for everything, a true evaluation must include a test drive.

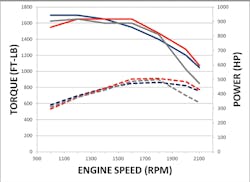

Take, for instance, a pumper at 42,000 pounds GVWR with a 500-hp diesel versus a 475-hp diesel. With the 500 hp, you will get a better power-to-weight ratio, and bigger is better, right? Not necessarily. Power-to-weight is often a metric kicked around by sports car buffs, but it won’t necessarily get you better performance off the line. Focus in on the low end of the torque curve and you will find that because the 475-hp engine reaches its peak torque of 1,700 lb./ft. at 200 rpm earlier in the curve, it moves out just as fast as the 500-hp engine, which reaches 1,650 lb./ft. at 1,200 rpm.

This approach to evaluating power performance characteristics will help departments better spec apparatus engines. It will help identify the benefits of low-end torque capabilities, which in turn will help reduce response times.

Because every second counts. Response time standards from the NFPA and the Commission of Fire Accreditation International (CFAI) call for engine companies to arrive at fire and EMS events in as little as four minutes. That’s 240 seconds. Low-end torque will help shave precious time from runs, especially those with many instances of “slow-n-go” at intersections and traffic blockage.