University of Extrication: Modifying Extrication for Electric Vehicles

Topic: Electric vehicle (EV) extrication

Objective: Understand EV extrication challenges

Task: The rescue team shall determine revisions and modifications that are needed for extrication procedures when EVs are involved

Responders realize that identification of any crash-damaged vehicle can be a challenge. When an electric vehicle (EV) is involved in a crash incident, particularly one that involves trapped occupants, identifying the make and model of the vehicle is very important to rescuers, because rescue procedures are specific for individual models. Even vehicles that are produced by the same manufacturer might have shutdown procedures or 12-volt battery locations that differ from one another.

Unique badging

Responders rely heavily on the exterior markings, or badging, that identify the make and model of the vehicle. Because all badging is optional for vehicles that are sold in the United States, EV manufacturers seem to be trending toward either no badging on their vehicle, adding badging that just has the manufacturer’s name (and not the vehicle model) or using badging that is referred to as unique.

Examples of unique badging that will be present on the exterior of upcoming EVs include: “OCEAN” and “PEAR” (Fisker), “AIR” (Lucid Motors) and “bz4X” (Toyota Motors).

This author uses the subscription-based Crash Recovery System (CRS) app from Moditech to quickly determine important rescue-related features about any vehicle, but particularly EVs.

If badging doesn’t reveal the make and model, the potential remains for the VIN to reveal what the vehicle actually is. The CRS app can work from that number.

For incidents that involve EVs, responders must obtain critical preplan information at the incident scene, and apps are the key to that opportunity.

Assuming that somehow the officer who is in charge of the incident does determine the make and model of the EV, when there are people trapped in the automobile, rescue personnel must be aware of several modifications to familiar extrication-related tasks. What follows below is a partial list of some of the more important EV extrication challenges and the recommendations for modifications that you should integrate into your rescue and extrication procedures.

Chock the wheels

It’s important at a rescue scene that involves any vehicle that sits on its wheels on a level surface for stabilization to be accomplished. When the collision involves an EV, chocking the wheels front and rear is critically important, as a means of preventing unwanted forward or rearward movement. With a powered-up EV, expect any unwanted movement to be silent yet potentially lethal to anyone who is in the path of travel forward or rearward. So, adopt the policy to chock the wheels.

Everything is electric

With an EV, as is the case with most late-model vehicles, think of everything as being electrically operated. Door locks, door latches, door windows and power seats, among other features, most likely will have electrical controls. For rescue personnel, a vehicle that has electrically operated door locks, power windows, a power liftgate latch, a keyless or smartphone ignition key system and onboard computer systems necessitates a slight change in the 12-volt power-down protocol.

If the rescue crew intentionally kills the 12-volt power at the actual 12-volt battery, any door or liftgate that still is closed and any door window that still is up is essentially frozen in that position. Without power to unlatch the doors, for example, they essentially act like jammed doors. With the electronic parking brake on an EV activated, without 12-volt power, law enforcement push bumpers can’t push, pull or drag the EV easily out of a travel lane to clear a minor incident.

Inside rescuers should unlock all of the doors electrically then open or, at least roll down, the power windows while the 12-volt power still is active—even if you don’t really need to do so at that time. You might regret your inaction once the 12-volt power is taken away.

Outside rescuers should be trained to add an additional but important step to the crash scene 12-volt power shutdown process: You should develop a protocol that requires that the rescuer who is at the 12-volt power source and ready to shut down the power not kill the 12-volt power before checking with inside rescue personnel to see whether they have operated all of the necessary electric features: doors, windows, liftgate, power seats, steering column, etc. If the inside rescue personnel say, “Go ahead,” then kill the power.

Taking away the 12-volt power without using any of the functional features of the EV might prolong your on-scene operation by making it more difficult for rescue and EMS personnel to do their tasks.

Ultra-high-strength steels

The newest vehicles are becoming more and more crashworthy, and this trend definitely includes EVs. One way for an automobile manufacturer to make its vehicle perform better in a crash is to incorporate ultra-high-strength steels (UHSS) into the structure of the vehicle.

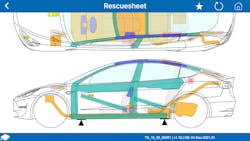

Floorpan-mounted battery

Placing large, high-voltage (HV) lithium-ion battery cells in a metal box that’s mounted beneath the floorpan of an EV is a game changer for rescue personnel. Besides the battery having a lithium-ion chemistry, its location and weight complicates several extrication assignments.

Essentially, the HV battery box is off limits during all extrication work. It isn’t to be crushed, bent or punctured during any rescue process. If extrication tasks cause physical damage to the HV battery, you must be prepared for the stranded energy that’s inside of the battery to cause a short circuit, which can result in a lithium-ion HV battery thermal runaway event, also known as a fire.

So, what extrication tasks have the potential to bend or crush the floor and the HV battery that’s beneath it? Consider dash jacking or dash rolling evolutions. When jacking the dash of an EV with a spreader, for example, the area of the floorpan that’s contacted by the bottom spreader arm must not be crushed or lowered in any way.

It’s the same situation and same caution when rolling a dash. When rolling the dash of an EV with a ram, you must be careful that the ram’s contact point on the rocker channel doesn’t puncture the floor or otherwise bend or crush the rocker or floor and damage the HV battery that’s beneath it.

Electric Vehicle Extrication Considerations

- Unique badging

- Chock the wheels

- Everything is electric

- Ultra-high-strength steel anatomy

- Floorpan-mounted lithium-ion high-voltage battery

About the Author

Ron Moore

RON MOORE, who is a Firehouse contributing editor, recently retired as a division chief with the McKinney, TX, Fire Department and now serves with Prosper, TX, Fire Rescue. He self-published the Vehicle Rescue 1-2-3 training manual and serves as the forum moderator for the extrication section of Firehouse.com . Moore can be contacted directly at [email protected].