The Impact of New EPA Emission Mandates for Fire Apparatus Diesel Engines

Key Takeaways

- The Environmental Protection Agency’s 2027 mandates regarding diesel engines, which focus on emission control systems and hardware, will have the biggest effect on apparatus design since 2010.

- 2027 diesel engines will generate the heat that’s required for selective catalytic reduction (SCR) solely with electricity, using a 48-volt DC, liquid-cooled alternator. The alternator will take up space that previously was occupied by the power steering pump, air compressor and 12-volt DC alternator, which will require the latter components to be moved.

- Engine doghouses will change in conjunction with the 2027 EPA emission mandates, although those changes aren’t defined completely at this time.

For the past couple of years, the major focus of fire apparatus purchasers and manufacturers has been the looming introduction of Environmental Protection Agency 2027 emission-compliant diesel engines. This process began with the 2007 emission mandates, and evolving diesel emission standards over the past 20 years drove many changes to the diesel engine and emission controls, some more visible to the user than others.

The 2027 changes that are required by the EPA, which focus on emission control systems and hardware, will have the biggest effect on apparatus design since 2010.

Emission control system

L9 and X12 engines will be discontinued and replaced with two versions of a completely new X10 engine. The medium-horsepower/medium-torque version of the X10 will have horsepower, torque rating and performance curves that mirror that of the L9 engine (450 maximum hp/1,250 ft.-lbs. of torque). The high-horsepower/high-torque version of the X10 (450 maximum hp/1,650 ft.-lbs. of torque) will replace the X12 engine. Power and torque curves still are being finalized for this version, along with other changes, so that the engine matches the outgoing X12.

An X15 engine still will be available, but it will be a different version of the X15 that currently is available.

The actual engine change date is Jan. 1, 2027, but any new apparatus that’s ordered now probably will be fitted with a 2027-compliant engine because of the current order backlog.

The technology and function of the emission control system won’t change. For clarity, regeneration is the self-cleaning cycle for diesel particulate filter (DPF) and is performed as needed to remove filtered particulate matter and to maintain flow through the exhaust system. Selective catalytic reduction (SCR) chemically converts oxides of nitrogen (NOx) into gases that are less harmful to the environment, utilizing diesel exhaust fluid (DEF) and/or heat. SCR takes place whenever the engine is running.

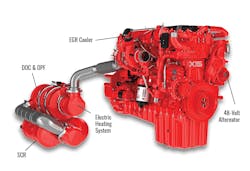

Because EPA mandates are to lower emissions with a large emphasis on NOx reduction, operational and design changes to the emission control system will be necessary. Currently, when extra heat is needed for SCR, it’s created by dosing raw diesel fuel into the exhaust system. The 2027 engines will generate the additional heat that’s needed for the SCR process solely with electricity, using a 48-volt DC, liquid-cooled alternator. This is a sealed unit that’s used exclusively by the emission control system. This alternator takes up space that previously was occupied by other mission-critical components (power steering pump, air compressor, 12-volt DC alternator, etc.), which will require moving those components and changes to the engine tunnel.

The SCR and the DPF, both of which are housed currently in a single canister, will be separated into two units, similar to the 2010 engines. Both units will be significantly longer, and the SCR will become a side-by-side unit that has been described as peanut-shaped.

Heat management

The hardware changes and additions that are noted above present real design

challenges for all apparatus manufacturers. Since fire apparatus engines are packaged into tight little boxes in the middle of the cab assembly, cooling the engines in custom fire chassis always has been difficult. It’s very complicated to move the needed cubic footage of airflow for proper cooling. It’s even more challenging to control the turboboosted charge air temperature. Fire pumps, front suctions, torque boxes and outrigger/jack support assemblies compound design challenges and further complicate fitting all of the firefighting components into the chassis with the vehicle operational components.

Engine doghouses also will change. As is the case with so many elements of this process, those exact changes aren’t defined completely. Expect to see a bump-out to accommodate hardware that’s relocated to accommodate the 48-volt emission control power supply. I saw one photograph of a new-style doghouse that has a step-out at the rear where it meets the cab floor.

Physically, the new engines won’t get much larger. I believe that the bigger problem will be heat management, which will dictate the form and size of the new engine enclosures.

Changes in the exhaust system hardware will present bigger challenges. Fire apparatus manufacturers must follow design and layout protocols from the engine manufacturers, and all layout options must be approved. Engines must be put into cabs and given extensive testing to see whether operational temperatures can be maintained in compliance with specifications. Consider that for a minute: These engines that are mounted in the cab and chassis assemblies must be capable of pumping at capacity while the engine and emission control system maintains coolant temperature, engine oil temperature, charge air temperature, transmission temperature, and emission control system function and temperature whether it’s a July afternoon in Phoenix or a January night in Alaska.

Effects of the changes

At the Fire Apparatus Manufacturers’ Association Apparatus Symposium in October 2025, there was an excellent presentation on some of the effects of these changes. Although far from extensive, the presentation discussed many of the challenges for both engine manufacturers and cab and chassis manufacturers. It also covered some of the adjustments that we might see. Some of the information that follows is from that conference, while some is from discussions that I had with others in the industry.

Expect to see changes to battery boxes and DEF tanks and possibly some cab layout changes. Specifics will vary from manufacturer to manufacturer.

Spartan will discontinue the cabs that have the 67½- and 74-inch cab-to-axle measurements; it will continue to manufacture the cab that has the 70-inch cab-to-axle measurement and will add a 77-inch cab-to-axle version.

With the exhaust system running along the right-side chassis rails, one expert believes that the R-1 compartment floor will be approximately 6–8 inches higher than that of current offerings.

Work in process

Because this is an incomplete picture of the changes and their effects, I contacted representatives of multiple manufacturers, including Faisal Naveed, who is the business unit director for cab, chassis & electrical at Pierce Manufacturing. Pierce’s team responded with some additional information:

- “The minimum ‘combined’ front body/pumphouse will be 45 inches, which is similar to what it is today. For example, if a 34-inch pumphouse is required, there will be a required 11-inch speedlay.”

- Pierce expects “very minimal impact to the cab itself. The only changes known right now pertain to small changes to the engine doghouse shape/dimensions and some possible impacts to some storage compartment option dimensions.”

I didn’t receive a specific answer about whether front suction still will be 5-inch piping or whether it would be reduced, but Pierce stated that it expects the front suctions to be “the same as we have today.”

Although it can be frustrating to have so few definitive details, it isn’t an indication that anything is wrong. The testing process for these 2027 engines is extraordinarily comprehensive, must be done in each cab and chassis combination for each version of the engine that’s offered, and can’t begin until cab and chassis manufacturers receive engines.

Understandably, manufacturers don’t want to provide information that might later be disproved nor say that they will discontinue a feature that turns out to be compliant when testing is done.

I strongly believe that this information will change as the year and the testing cycles progress and fervently hope that we learn more from cab and chassis manufacturers soon.

About the Author

Jeffrey D. Gaskin

Jeffrey D. Gaskin is president of Big Red Trucks Fire Apparatus Consultants. He is a retired captain from the Scarsdale, NY, Fire Department. Throughout his career, Gaskin has been involved in apparatus acquisitions, from needs assessment through specification-writing. He also is a fire apparatus mechanic and holds certifications from Allison Transmission, Detroit Diesel, Hale Pump, Smart Power, Spartan Chassis, Sutphen Fire Apparatus and others. Gaskin is certified by the Emergency Vehicle Technician Certification Commission in six areas: Fire Apparatus Inspection, Maintenance and Testing (F-1); Design and Performance Standards of Fire Apparatus (F-2); Fire Pumps and Accessories (F-3); Aerial Fire Apparatus (F-5); Allison Automatic Transmission (F-6); and Hydraulic Systems (F-8). He can be reached at [email protected].