Whether at trade shows or in person, a subject that’s often raised by members is metering. How and why do we do it? What do the numbers mean? What do I do with the numbers?

Members seemingly are overwhelmed. Even members who have been doing metering for a long time wonder, “Why is it so difficult to understand?” Newer members press for details, because they frantically are searching for anything to help them to operate more efficiently.

The process of metering is vitally important for all levels of hazmat, because it does what we humans can’t: detect what’s in the air that potentially can harm us. Our noses are rather good at some things: smelling hazmat, not so much. Further, metering lets us know the amount of contaminant that’s in the air, so we can make tactical decisions, such as where to run, what to wear and how quickly to move.

Metering has served us faithfully for many years, but one of the major initial problems in this disconnect from our senses is turning over the controls to something that only gives us a number or a sound. What was internalized now is externalized, and we use more knowledge and understanding than gut feelings to make a decision.

Why we monitor

Meters establish a few important parameters for all members to operate safely. For instance, they establish zones for both responders and the public. In big terms, we use the zones “cold,” “warm” and “hot” based on meter readings. However, even “hot” can be broken into levels, including permissible exposure limits (PEL)—or SCBA on—and immediately dangerous to life and health (IDLH)—or change your PPE and mitigation-area boundaries.

Meters also can be used to locate a leak to a specific area and to determine whether an atmosphere is flammable, toxic or corrosive. Each of those might require a completely different choice of PPE, and, from where we sit, that’s very important information.

Finally, meters are used to simply find out whether actions that are taken are having an effect on the operation. “We closed a valve. Did it work? Check the meter.”What do we meter first?

This bring us to the question, “Why do we need to know what those numbers or beeps mean?”

Every meter out there reads something that we humans can’t but in a slightly different way. (Tons of meters are on the market, but we won’t speak about brands or models. If we wrote about brands and models this month, next month we would need to rewrite this article, because the market turns over that quickly.)

Meters bridge a gap between our senses and the true danger of the area. In some cases, our senses won’t let us know that there is a problem until after the toxin is in us.

There is no hard and fast rule to the order of metering, and the order that we apply might be different than others. However, there is a method to our madness.

First, we monitor for radiation. This is because radiation is one of the hazards that can get to us from the farthest away. Though radiation often is a doomsday situation in the movies, in reality, with proper precaution and a little math, this genre of hazmat usually is one of the easier to mitigate.

Second, we monitor for flammability, because, when this is a concern, there usually is an urgent reason for ensuring that the correct PPE is being used.

Third, we monitor for oxygen, because that can change the rules of the game. Low oxygen levels can result from asphyxiant gases that exclude oxygen, such as carbon dioxide, and from gases that have a higher affinity for your red blood cells than oxygen does, such as carbon monoxide. There are other ways for oxygen to be reduced in the air—for example, biologicals consuming it and the process of rusting. When a low oxygen level exists, for the most part, easy peasy: Put on your SCBA. However, when the oxygen level is elevated, you can have some serious problems that must be figured out immediately. This elevation can be from peroxide decomposing or, simply, an oxygen tank being left open. In instances in which oxygen readings are elevated, things that we assume can’t catch on fire can.

Fourth, we monitor for toxicity, which provides a means for a quick size-up of how a hazardous material can get into your body. If the concern is inhalation or ingestion, put on your SCBA. (One must be mindful of abrasions and punctures, too.) If the concern is skin, now you have a problem. If the toxin is absorbable through the skin, the situation is more than likely beyond the capabilities of operations-level hazmat personnel. Level B or A is needed to mitigate this. If corrosives are on the ground, a Level B usually would be required to handle the situation. If the corrosive is in the air, a Level A might be considered.

In reality, we monitor things simultaneously. We go in with all of our meters and watch all of them at the same time. A member never runs in with a radiation meter, then runs out, gets the flammability meter and then runs back in.

Ready to go

Before we get to work with the meter, we must set ourselves up for success. We need to ensure that the meter and its components are ready to give both accurate and precise readings for us to make sound tactical decisions.

Calibration is the process of exposing the sensors that are in a meter to a set volume and concentration of gases to elicit a response. (If my calibration gas cylinder has 25 ppm of carbon monoxide and my meter shows 23 ppm, then the meter needs to be adjusted.) Today’s meters are markedly better in the realm of calibration than are versions from even just a decade ago because of their capability to automatically adjust the internal software.

Editor’s note: You might hear calibration referred to as “zeroing” a meter, but zeroing is a slightly different process, and it shouldn’t be confused with calibration. (See “Fresh Air Calibration” below.)

There is much debate regarding the need for a so-called bump test, in particular when and how to carry it out. The Occupational Safety and Health Administration (OSHA) defers to the manufacturers. Manufacturers’ stance varies significantly on the need and, then, on the process.

OSHA defines a bump test as “a qualitative function check in which a challenge gas is passed over the sensor(s) at a concentration and exposure time sufficient to activate all alarm settings.” Basically, the agency is saying to take a dry erase marker or something similar and place it temporarily in front of the sensor to get proof of alarm. We aren’t concerned with the actual numbers. We are concerned with the alarm working.

Also worthy of note: OSHA suggests that a bump test “should be conducted before each day’s use in accordance with the manufacturer’s instructions.”

Metering Terms

Response time: The time for a sample to be drawn into the meter and read and for a number to be displayed on screen, for the needle to move or for an audible signaled to be triggered. Two main types of collection methods directly affect this time: a diffusion mode entails sampling air in direct contact with the sensing area; a pump mode actively moves the sampled air through a hose from someplace remote to the sensor.

Sensitivity: How low of a level that a meter can detect something in the air or a subtle change of concentration. The more sensitive that a meter is, the better the resolution of the reading. Sensitivity differs greatly from sensor to sensor and from technology to technology.

Selectivity: How accurately a sensor or technology can read a specific gas or group of gases.

Operating range: The lowest reading to the highest reading. You would think that all meters read well from zero to the limit for the sensor, but this isn’t the case.

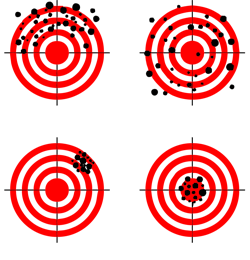

Accuracy vs. precision: These two different terms both are needed to give a complete understanding of a meter’s measurement. Accuracy reflects a grouping. Precision reflects an area. Think of it in terms of different skill levels of dart throwers. Someone who doesn’t throw darts much likely throws them all over the board. That person lacks precision and accuracy. Another person who has honed his/her skill can aim at the 20 section and land three darts in the section, but they are scattered in the section. That person has accuracy but lacks the precision to group the three darts close together. A terrific dart thrower can aim at the bull’s-eye and hit it with three out of three darts. This person has accuracy and precision: Not only was he/she able to throw the darts where desired, but he/she was able to do so consistently. If a meter lacks accuracy or precision, our tactics might suffer. (See Figure 1)

Cross-Sensitivities

Obviously, we want a meter that’s going to read the atmosphere for the substance that we want to measure. However, a meter that’s designed for a certain substance often reads other substances. In this case, the meter has cross-sensitivities. You might believe that this is a drawback, but it can be quite useful if understood.

An example of a useful cross-sensitivity would be that the carbon monoxide sensor on a standard carbon monoxide meter also can pick up hydrogen and acetylene quite well. (Most of us don’t have an acetylene or a hydrogen meter on the rig.) So, should your carbon monoxide meter register a substance in the air, but your ensuing investigation for sources of a carbon monoxide emission (fireplaces, furnaces, heating units) eliminate the possibility of carbon monoxide, your training and common sense must take over. In other words, if it looks like a duck and quacks like a duck, then it must be a duck. The meter is reading a substance. The meter isn’t reading carbon monoxide. Then the meter is reading a substance that shouldn’t be in the atmosphere.

The bottom line: Don’t have tunnel vision. Be aware that cross-sensitivities exist (dozens, in fact). Determine whether the meter is reading something other than the primary substance and act accordingly.

Fresh Air Calibration

Fresh air calibration allows a user to zero a meter in the field. (It seems as if each manufacturer calls this process something different, and they might abbreviate it on screen.) Although this seems to be a great advantage, without knowing the ramifications, it could have terrible results. For example: A junior firefighter is told by his chief to get a meter for a carbon monoxide alarm in a house. While getting ready in the rig, the firefighter forgot to turn on the meter and now is cursing himself in his head for not doing it: his chief doesn’t like to look unprofessional. So, the firefighter quickly powers on the meter and muffles the test sequence sounds with his gloved hands. The chief tells him to check out the house, but the meter still isn’t ready. The fresh air setup (FAS) screen appears, but the firefighter knows that if he presses “Yes” that the meter almost immediately will go to the regular reading screen. Nevertheless, he pushes “Yes” and begins to meter. He tells the chief that there are no readings, and they leave.

What was the problem? When the firefighter pushed the FAS, he told the meter that the air where he stood wasn’t contaminated, when, in reality, contaminants might have been present in the air where he was. This misstep or misunderstanding can cost lives.

Only use the FSA function when you reasonably can presume that the air that’s around you has zero contaminants.

About the Author

Bobby Salvesen

Bobby Salvesen retired in 2022 after more than 25 years of service with FDNY and Hazmat Co. 1. He is a Nassau County, NY, Fire Service Academy hazmat instructor and is co-host of The Haz Mat Guys podcast. Salvesen studied chemistry at New York Institute of Technology, SUNY-Old Westbury and SUNY-Empire State.

Michael Monaco

MICHAEL MONACO is an 18-year veteran of the FDNY. He has been assigned to Hazmat Company 1 for the past 15 years. Monaco holds a bachelor of science degree in biochemistry. Bobby Salvesen and Monaco co-host “The Hazmat Guys” podcast.