Manufacturer's Corner: Five Tips for Choosing the Right Particulate Hood

Manufacturers’ Corner content is sponsored by manufacturers and suppliers serving the fire service industry.

The fire industry has become increasingly aware of the potential relationship between exposure to fireground particulates and your safety and health. Firefighter studies have shown that some of your most vulnerable areas are around your neck and ears, despite being covered by your hood. With the addition of the Particulate-Blocking option for hoods in the 2018 Edition of the NFPA 1971 Standard, manufacturers are now offering particulate hoods in a variety of styles and designs. Before purchasing a particulate hood, you should consider several key factors.

Testing for particulate protection

First and foremost is the level of protection that the hood provides against the particulates you may be exposed to on the fireground.

For the particulate-blocking hood option, the NFPA Standard requires that hoods block at least 90 percent or more of the particulates with a size from 0.1 to 1.0 microns (µm). This test is performed on six specimens cut from rolls of material used to make the hoods. Three of the specimens are preconditioned, which includes 20 launderings and two convective heat cycles. The other three specimens are tested without preconditioning. If the average percent efficiency of these specimens is 90 percent or greater, the hood meets the requirement. The higher this percentage is, the more protection the hood is likely to provide.

System-level testing of the hood

While the particulate-blocking test provides good information about the ability of the hood’s materials to block particulates, it is also important to evaluate the entire hood’s performance in the environment it will be used.

Using the Fluorescent Aerosol Screening Test (FAST) is an excellent way to gain valuable data about the hood’s ability to provide protection on a system-level (i.e., when being worn as part of an ensemble). This test is not part of the Standard’s requirement, but it is important, because wearing the hood as part of an ensemble could impact its particulate-blocking performance.

For example, Gore contracted an independent laboratory to perform the FAST test to verify the GORE® Particulate Hood’s performance compared to a traditional (i.e., non-particulate) hood as part of a full ensemble, including gear, mask, and SCBA.

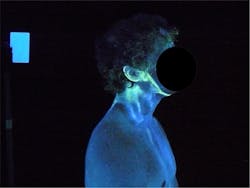

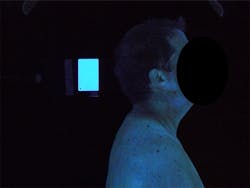

The following image shows FAST test images for three scenarios:

- a traditional hood, donned with gaps at the hood-to-mask interface

- a traditional hood, donned properly without gaps at the hood-to-mask interface

- a GORE® Particulate Hood, donned properly without gaps at the hood-to-mask interface

The three bright rectangles on the left of each image are the same paint chip. This chip is used during photography as a color standard to show changes in lighting due to the amount of fluorescence on each subject’s skin.

The image on the left shows the particulate ingress that occurred when a small gap between the SCBA mask and the hood elastic left an open path for particulates to travel. A gap as small as a few millimeters can have a drastic impact on a firefighter’s level of protection. Note that the paint chip in this image appears darker compared with the other two chips; this is because the camera automatically compensated for the higher amount of fluorescence from greater particulate penetration through the interface gaps.

The middle image is an example of what everyone knows about PPE: properly donned PPE maximizes protection. It shows a traditional hood that was donned properly (i.e., the hood’s elastic band was flat on the gasket around the entire SCBA mask). The areas without fluorescence that are below the ear were from the SCBA mask strap tight against the skin. However, a significant amount of particulate was still visible on this subject’s skin. Therefore, to minimize this particulate ingress, additional steps still must be taken beyond wearing a properly donned traditional hood.

The image on the right shows that when a GORE® Particulate Hood was worn, no visible evidence of particulates on the subject’s skin could be found.

Focus on breathability, not air permeability

You may hear about the air permeability of a hood; however, air permeability is a two-way street. Products with higher air permeability may allow more air and also more particles to travel into the hood, potentially decreasing protection against fireground contaminants.

Breathability is not the same as air permeability. Hoods can maintain good moisture vapor breathability without being air permeable. Total heat loss (THL) contains a moisture vapor breathability component. The 2018 edition of the NFPA 1971 Standard requires a minimum THL value that all particulate hoods must achieve for certification. Therefore, when selecting a particulate hood, make sure it has both good breathability and a higher particle-blocking efficiency, so that you know it delivers a better balance of comfort and protection.

Durability for long life

Another issue the industry is focusing on is the need to keep your gear clean, which means that you wash your hoods frequently. The 2018 edition of NFPA 1971 Standard defines preconditioning as 20 launderings and two convective heat cycles. With the strong focus on cleaning your gear, you most likely need to wash your particulate hood more than 20 times, and you should expect your investment in increased protection to last longer.

Therefore, you should see how extensively the durability of the particulate hoods you are considering has been tested. For example, Gore washed GORE® Particulate Hoods 100 times at a verified ISP and repeated both the Particulate Blocking Test and the FAST test to evaluate its particulate-blocking performance. The results showed that specimens from these laundered hoods maintained their 99.9% particulate-blocking efficiency — the same as the results for the specimens tested from new hoods and those tested after NFPA preconditioning (i.e., 20 launderings and two convective heat cycles).

Design features for protection

As with turnout gear, manufacturers develop their hoods with different design features, and you should evaluate these as part of your decision process. For example, some particulate hoods are designed with protective barriers in selective areas of the hood — such as around the neck and ears — while others have protective barriers throughout the entire hood.

Another design factor that cannot be underestimated when evaluating gear is your ability to inspect it visually. Some manufacturers include an inspection opening in the hood that allows you to invert it and inspect the protective barrier for cuts, holes, and tears and then turn it right-side out again.

When you are selecting a particulate-blocking hood, it is important to understand testing methods used in the industry as well as the various design options available. Not only do the results of these tests show the differences between particulate hoods, but with that knowledge and researching the benefits of various hoods, you can select a hood that delivers the best and most reliable protection you need. For more information about these test methods, visit GOREHoods.com to download a white paper, Ensuring Certified Protection and Long-Lasting Durability in Particulate Hoods.