'Crash Course' Quick Drill Series - Part VII

It is now common that one vehicle will have at least three different metal types, each with a different composition, strength, and from our perspective, a different cutting action.

Topic: Exotic Metals in Our "Cut Zone"

Automakers continue to increase the various types of metals used in the construction of their vehicles each year. It is now common that one vehicle will have at least three different metal types, each with a different composition, strength, and from our perspective, a different cutting action.

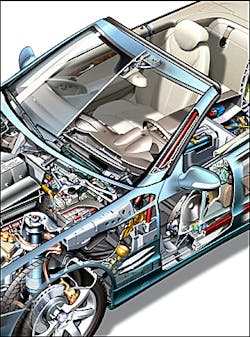

The images of the Mercedes-Benz SL convertible typifies the challenge of these exotic metals. Note that the artist's rendering of the A-pillar reveals a dark red metal. As you can see in the close-up view, this structural member contains an inner, rod-shaped assembly. It is ultra high-strength Boron metal.

The A-pillars and windshield header and frame are reinforced by high-strength-steel tubes sandwiched between reinforcements of Boron steel. Boron, a type of steel, is superior in strength to other steels, has high fatigue strength and greater wear resistance.

Other new structural materials such as aluminum laminates, plastic-steel laminates, carbon laminates, and hydroformed frames are already appearing in luxury vehicles.

Crash Course Teaching Point:

- Ultra high-strength steels such as Boron are difficult if not impossible to cut with certain rescue tools. Air chisels won't even make a dent. Reciprocating saws can't even scratch it. Only a few hydraulic rescue tool manufacturers have cutters capable of even attempting to cut through Boron roof pillars. Chances are, unless your hydraulic power cutter is brand new it may not be able to cut through this material either.

- If you have old cutters either upgrade to a cutter that has been proven to cut through Boron or come up with rescue options that do not require Boron roof pillars to be cut.

Be Informed...Be Ready...Beware!